HZS180 concrete mixing plant

HZS180 concrete mixing plant

Major advantage:

1, excellent performance

Double horizontal shaft forced mixer has strong mixing capacity, uniform mixing quality and high productivity. Good mixing effect for concrete with dry rigidity, semi-dry rigidity, plasticity and various proportions. Lubrication system, spindle transmission system can be imported with a full set of original, the hydraulic door opening mechanism can adjust the opening of the discharge door according to needs. The mixing shaft of the mixer adopts anti-adhesion technology to effectively prevent the cement from caking on the shaft. The sealing of the shaft end adopts a unique multiple sealing structure to effectively prevent the sand from leaking and ensure the continuous operation of the entire mixing system. Cleaning system adopts high pressure water pump automatic control and manual control,

Each water outlet hole is located directly above the mixing spindle, which improves the mixing efficiency, increases water mist, reduces dust pollution and effectively removes cement caking.

2, environmental performance

All powder materials, from feeding, dosing, metering, feeding to stirring discharge are carried out in a closed state. The dust pipe of the mixer cover, cement metering bin and fly ash metering bin is connected with the dust collector, and the dust blocking plate is set at the aggregate filling port to reduce the dust emission. The fully enclosed mixing main building and belt conveyor structure reduce the pollution of dust and noise to the environment. The use of negative pressure dust removal and special fiber filter cloth, so that the dust generated when feeding into the dust collector does not spread around, and the collected dust can be easily recycled and reused, effectively protect the environment. Users can also choose imported dust removal system.

3, reliable performance

The mixing blade is made of unique high chromium and high manganese alloy wear-resistant material, and the shaft end support and sealing form are made of unique multiple seals, which improves the reliable performance of the main engine. The wear-resistant steel plate is used to reinforce the inner part of the frequently affected and vulnerable places, such as: discharge hopper, transition hopper, etc. The ring belt joint is vulcanized and bonded, and the service life is 3 times longer than that of ordinary steel riveting.

Good mixing performance: the maintenance and repair parts of the whole equipment are provided with a platform or access ladder, which is convenient for inspection and maintenance operation, and the main engine cleaning is provided with two sets of pumping and manual operation. Platform building structure and aggregate belt conveyor fully closed structure, to ensure that all operations can be carried out normally. The belt conveyor with closed form is provided with overflow outlet at the lower part, which can effectively prevent sand and stone from scattering everywhere. The belt conveyor adopts the rehanging tensioning structure, which eliminates the adjustment work in the production process.

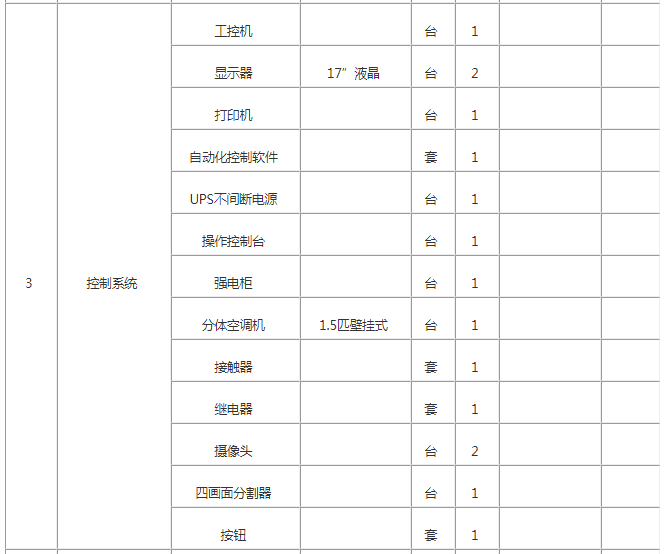

4. Operating system

The machine is controlled by computer, which can be controlled automatically or manually. The operation is simple and convenient. The dynamic panel displays the operation of each component of the mixing station (building), and can store various data of the mixing station (building), print all kinds of report data as required, and store more than 30,000 formulas. The control room is spacious, bright, beautiful, and equipped with air conditioning to ensure durable electrical components and stable and reliable performance. The control system adopts the form of dual control, and the data is shared between the control machine and the management machine. When the control machine fails, it can be transferred to the management machine to ensure the continuous normal operation of the system to a certain extent. Monitoring cameras can be set in key components such as discharge port and dosing station of the main engine.

5, electric control system introduction

The electronic control system adopts dual control form, that is, the system is composed of two high-performance industrial computers, one as the main control production system, and the other as the management and monitoring system (also as the backup machine of the main control production machine), using a special batching control instrument. As the main control system, it has manual and automatic functions. Industrial computer through external sampling, after calculation, comparison, processing, output control of external driving components, so as to truly realize the mixing station (building) computer control. Manage and monitor the computer system as a backup system of the entire electronic control system, in case of problems with the main computer, the user can choose the backup machine system to work.

To ensure that the machine is running properly at all times, so as not to affect your production. The system has the function of printing statistical production daily report, monthly report, online detection and monitoring. At the same time, it has a fault diagnosis help system to guide users to repair. The manual button system on the panel of the operation station can complete the functions of automatic control of batching, unloading and manual control of concrete output.

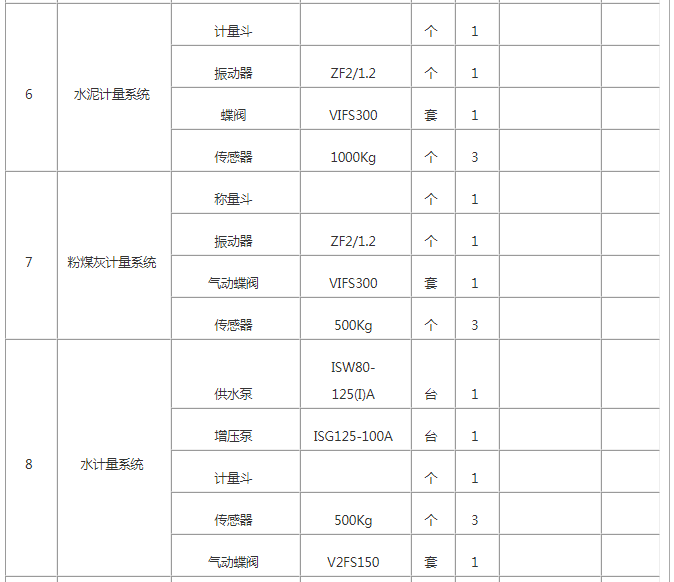

6. Measurement performance

Whether it is the weighing of aggregate, powder or water agent, its weighing, control, signal conversion components can be imported components, high-precision sensors, imported microcomputer control, each scale weighs separately (or cumulative weighing), to ensure accurate measurement and stable working performance

7. Weighing system

Cement, fly ash and other powders are transported to the weighing hopper by the screw. Water and liquid admixtures are controlled by pneumatic butterfly valve and ball valve, with good sealing and fast action to ensure weighing accuracy. The water enters the mixer through the booster pump pressurized injection, so that the water is mixed with the mix faster, and the cleaning is more thorough.

8. Stir the main building

Using H-shaped steel as the main beam,

the structure is stable and reliable, and the vibration resistance is strong. The cables and gas pipes in the building are arranged with special wiring slots, which is neat and beautiful and conducive to protecting the cables. The outer seal is made of pressed color steel plate, which is beautiful and generous. Thermal insulation layer can be added as needed to adapt to the cold weather in the north.

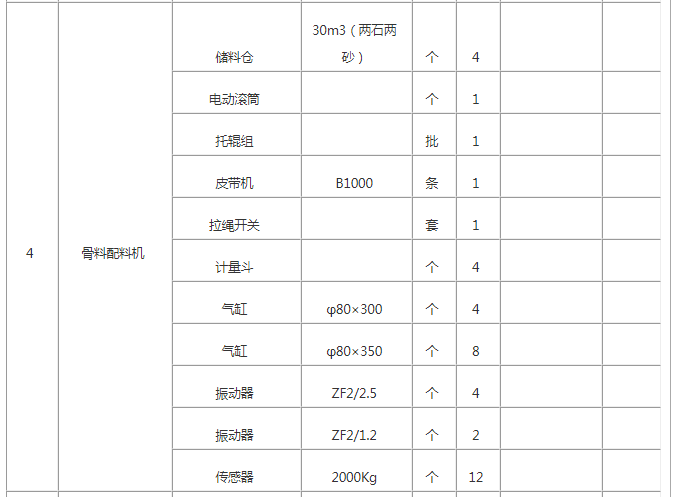

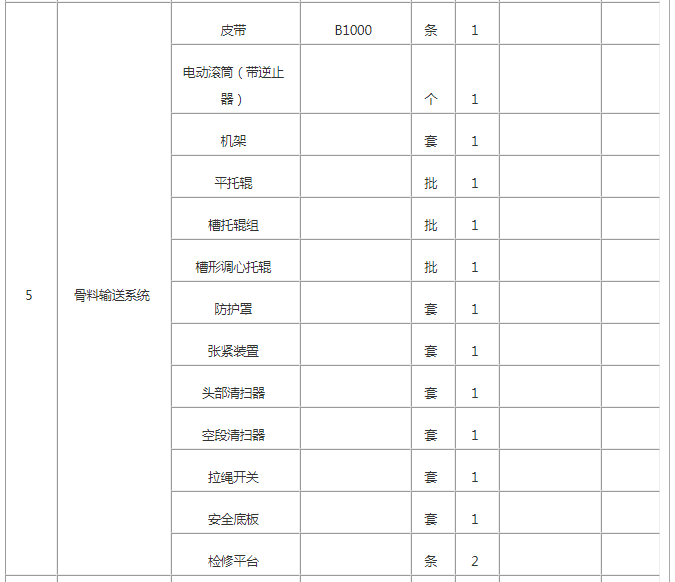

9. Conveying device

Three to five bone silos can be provided as required, and the lower part of the bone silo is a separate aggregate weighing hopper and aggregate release belt machine. Feed the bone bin with a loader or belt conveyor. The silo can be designed as steel structure. The lower part of the silo can be selected with less moisture content measuring instrument. The inclined belt conveyor is responsible for delivering the aggregate to the transition storage bin. The inclined belt is tensioned with a heavy hammer and works reliably. The conveyor Angle is less than 18°.